COMPRESSOR

DIESEL

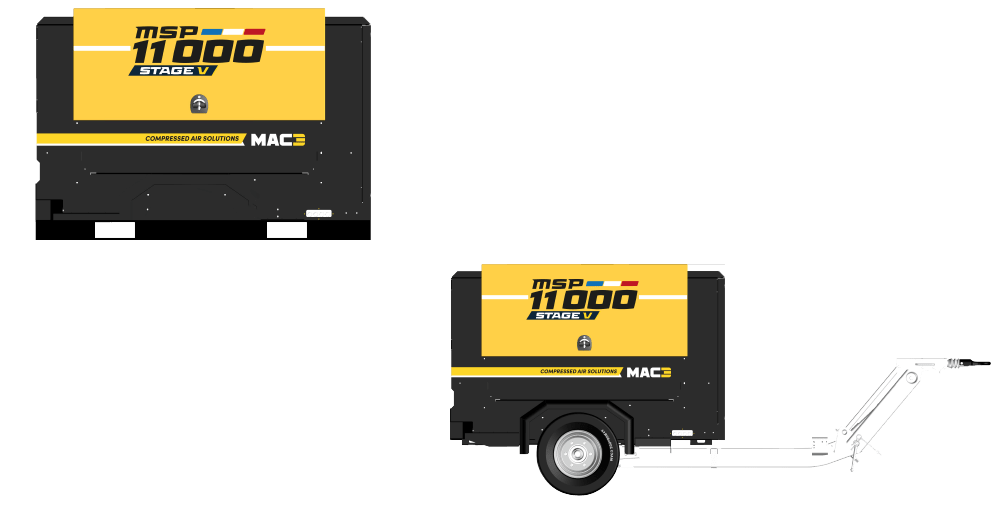

MSP11000 STAGE V

MSP11000 STAGE V compressors are recognized by construction professionals for their reliability and performance. Customizable and adaptable, the 11000 l/min model is designed for regulated zones*.

VERSATILE AND POWERFUL COMPRESSORS

MSP, COMPRESSORS ADAPTED TO THE REQUIREMENTS OF THE CONSTRUCTION INDUSTRY

MSP compressors are the most compact machines on the market. Thanks to their design and the optimized layout of their internal components, MSP compressors feature a balanced axle weight distribution, for improved maneuverability on site.

The design of the MSP series also provides excellent accessibility to the main compressor components. This feature is critical to facilitate maintenance and reduce compressor downtime.

KUBOTA ENGINE

The MSP11000 STAGE V compressor is equipped with Kubota engines. Recognized worldwide for the quality of its components, the Japanese firm and MAC3 have been working together for many years to offer the highest-performing mobile compressors for construction sites.

DOCUMENTATION

-

To access more materials, please visit

.

2 COMPRESSOR CONFIGURATIONS

MSP COMPRESSOR: VERSATILE AND ADAPTABLE

The MSP11000 compressor is available in 2 different configurations to meet the needs of construction professionals:

- Standard SKID compressor, including remote drain.

- Braked axle compressor,

FIELDS OF APPLICATION

SPECIFICATIONS

PERFORMANCE

| MSP11000 STAGE V | |||||

|---|---|---|---|---|---|

| Working pressure | 7 bar | 8.5 bar | 10 bar | 12 bar | 14 bar |

| 100 psi | 125 psi | 145 psi | 170 psi | 200 psi | |

| Air flow | 10.5 m³/min | 10.5 m³/min | 10.5 m³/min | 10.5 m³/min | 9.7 m³/min |

| 370 cfm | 370 cfm | 370 cfm | 370 cfm | 342 cfm | |

| Noise level | 99 db(A) LWA | ||||

| Compressor oil circuit | 41 L | ||||

| Compressed air outlets | 1 x 1/2 + 3 x 3/4 | ||||

MOTORIZATION

| MSP11000 STAGE V | |

|---|---|

| Engine | KUBOTA V3800 |

| Power rating | 96.4 kw |

| 129.2745 hp | |

| Fuel tank | 170 L |

DIMENSIONS AND WEIGHT

| MSP11000 STAGE V | ||

|---|---|---|

| Standard SKID | Braked axle | |

| Dimensions | 2252*1218*1588 mm | 4361*1788*1939 mm |

| 88 x 48 x 62 in. | 171 x 70 x 76 in. | |

| Weight | 1850 kg | 2150 kg |

| 4078 lb | 4740 lb | |

* The Stage V and TIER 4 regulated zone is a regulatory classification defined to control emissions from diesel engines used in non-road equipment, such as compressors. These standards have been developed to reduce harmful emissions from these engines, such as fine particles, nitrogen oxides (NOx) and hydrocarbons.

Stage V is a European regulation, while TIER 4 is an American standard. Although different in their technical specifications, these standards pursue the same objective of reducing pollutant emissions.

Equipment complying with Stage V and TIER 4 standards is equipped with advanced technologies such as Diesel Particulate Filtration (DPF), Selective Catalytic Reduction (SCR) and Exhaust Gas Recirculation (EGR) systems. These technologies enable exhaust gases to be treated before being released into the atmosphere, significantly reducing pollutant emission levels.