6. TESTS

Before being packaged and engraved on its nameplate, every pneumatic tool manufactured is tested and must meet all the performance criteria that characterize it.

MAC3 attaches great importance to the quality of its products, which is why the company selects the best components for the manufacture of its pneumatic tools. MAC3 spades and breakers are manufactured entirely at the company's St-Cyprien production site, in the heart of the Auvergne Rhône-Alpes region. MAC3 invites you to immerse yourself in its factory, where you'll discover how a piece of metal becomes a high-performance concrete breaker or pick.

The first stage in the manufacture of MAC3 spades and breakers is the drilling of the steel billet. Several drills of different diameters are used to drill the center of the billet, forming the internal architecture of the future tool and enabling the cylinder to retain its concentricity.

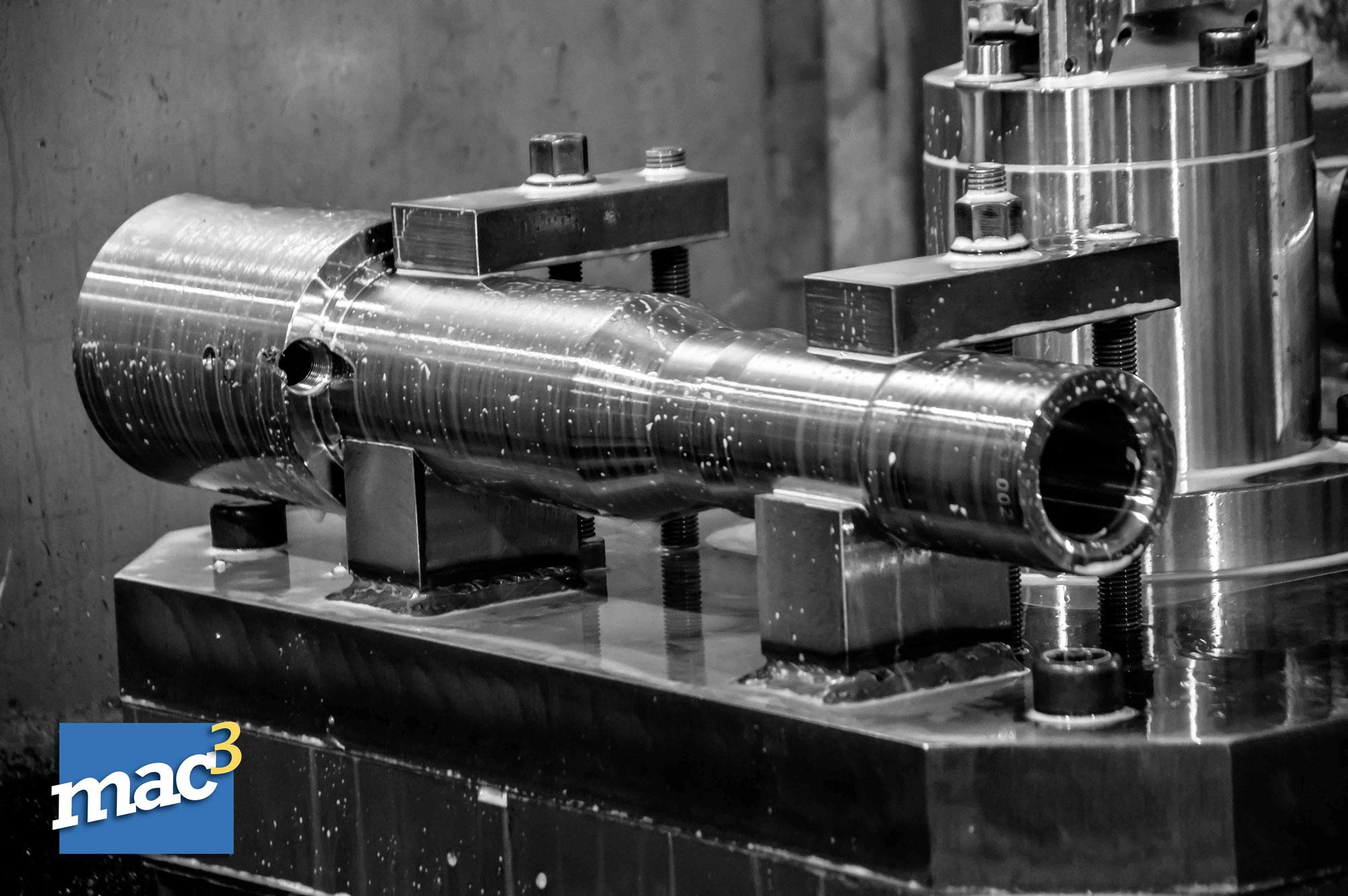

Once the internal holes have been drilled, the part is placed in a CNC lathe for external machining. This first machining operation profiles the monobloc cylinder.

Once this work is complete, the semi-machined cylinder is placed in a machining center, where the various screw threads and tool feed and circulation ducts are drilled.

The one-piece cylinder is then subjected to electro-erosion, a process which removes material by means of electrical discharges. This technique offers the advantage of very precise machining, and is used by MAC3 to make final adjustments to the cylinders.

Finally, each cylinder is engraved with a unique serial number.

After machining, the monobloc cylinders are sent to a regional subcontractor for heat treatment. This type of treatment enhances the steel's intrinsic technical performance.

Once machining and processing have been completed, tool assembly can begin. This begins with the combination of cylinder and sleeve, which are assembled by the action of a press. Next, all the internal components of the future concrete breaker or spiker are installed: piston, distribution and seals.

Finally, the handle is mounted and secured to the top of the tool.

MAC3 jackhammers and pickers have the advantage of rapid assembly, thanks to their low parts count and optimized design. The reduced number of components is a definite advantage in terms of tool reliability and maintenance.

Before being packaged and engraved on its nameplate, every pneumatic tool manufactured is tested and must meet all the performance criteria that characterize it.