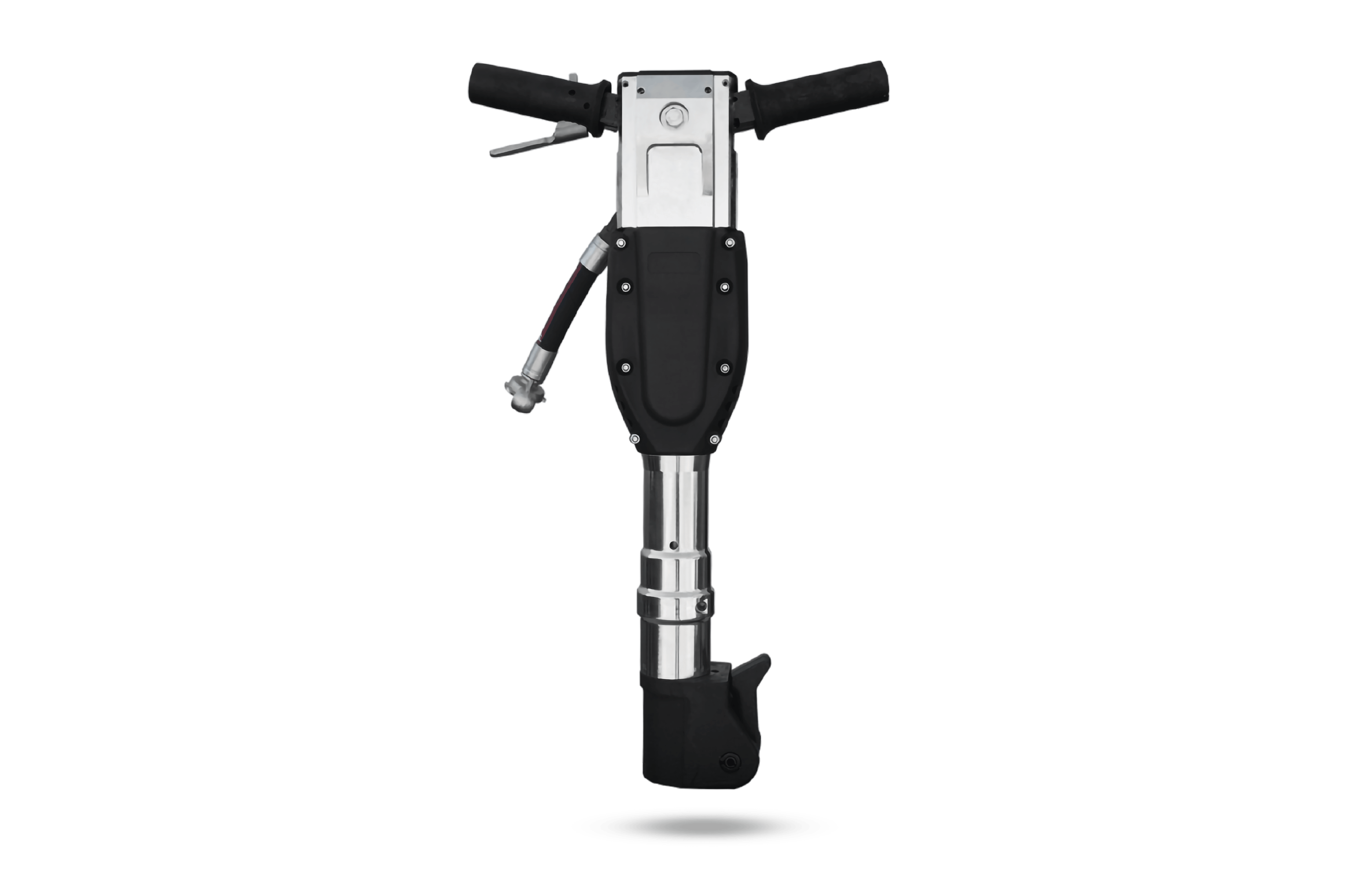

SANDING MACHINE

S70

MAC3's S70 sandblaster is the ideal tool for stripping any vertical or horizontal surface. Versatile and easy to handle, it is ideally suited to masonry renovation, facade restoration, paint removal, rust removal and metal surface preparation.

PROFESSIONAL SANDBLASTER

VERSATILITY OF USE

The MAC3 sandblaster is a blasting solution that uses compressed air to project abrasive. Its operation consists in putting a tank, previously filled with abrasive, under pressure.

The MAC3 S70 sandblaster ensures the stripping of all types of horizontal or vertical surfaces for :

- masonry renovation ;

- Building façade renovation;

- Paint removal;

- Rust removal and preparation of metal surfaces.

Recognized for its efficiency and ease of use, the MAC3 sandblaster combines comfort, performance and safety.

DOCUMENTATION

-

To access more materials, please visit

.

A "CARING FOR PEOPLE" SANDBLASTER

SAFETY IN USE

- Easy access to the hatch

- Remote control system

- Automatic closing

- Protection of the closing cone

- Service pressure tank set at 10 bar

COMFORT

- Stretcher-type transport support

- Ergonomic dimensions

- For the blasting helmet kit

- Activated carbon filter for helmet supply

- Integrated air intake for headphones

ECONOMY

- Sandblasting setting

- High resistance integrated air purifier

- Tank with optimized capacity of 70 L

PRESSURE BLASTING TECHNOLOGY

SANDBLASTING MACHINE : WHY CHOOSE THE PRESSURE TECHNOLOGY ?

Pressure blasters are the models to be preferred for professional use.

The operating principle of this technology guarantees constant performance: the aggregates are contained in a sealed tank under pressure. Pressing the trigger of the gun releases this pressure and thus the aggregates at the same time. The pressure and the flow rate at the gun outlet are regulated and constant, which allows powerful and intensive stripping.

The MAC3 pressure blaster offers several settings, allowing of course to sand, but also to airbrush (low pressure operation) if the nozzle mounted on the gun is adapted.

The pressure blaster requires a significant air flow (2500 l/min minimum) to operate properly, which implies the use of a mobile compressor such as the MAC3 MSP range.

FIELDS OF APPLICATION

SPECIFICATIONS

TECHNICAL DATA

| Dimensions (L*W*H) | Weight | Working pressure | Piping | |||||

|---|---|---|---|---|---|---|---|---|

| S70-10 | 600*680*1165 mm | 23,6*26,8*45,9 in. | 70 kg | 154.3 lbs. | 7 bar | 100 psi | 10 m | 393.7 in. |

| S70-20 | 600*680*1165 mm | 23,6*26,8*45,9 in. | 70 kg | 154.3 lbs. | 7 bar | 100 psi | 20 m | 787.4 in. |

Directions for use:

- Nozzle diameter 8 = compressor 5000 l/min

- Nozzle diameter 6,5 = compressor 3000 l/min

- Nozzle diameter 5 = compressor 2500 l/min

EQUIPMENT

Sandblasting kit including :

- S70 sandblaster with remote control

- Complete piping (length to be chosen)

- Carbide nozzle (size to be chosen)

- Water filter for the sandblaster

Sandblasting helmet kit :

- Shot-blasting helmet with window and feed hose (length to be chosen)

- Activated carbon filters for the helmet