MSH MAC FARMER VS USED DIESEL COMPRESSOR

In everyday farm operations, a compressor is an essential tool. Whether cleaning equipment (combine harvesters, balers, forage harvesters, manure spreaders, mowers, etc.) or powering pneumatic tools, farmers require airflow, pressure, and power — with reliability, availability, and minimal technical constraints.

A Controlled Investment vs. Unpredictable Costs

Compared to a used compressor — often perceived as a cost-effective solution — the MSH MacFarmer deserves an objective comparison. Because beyond the purchase price, the lack of warranty, inherited wear and tear, and uncertainty regarding previous maintenance weigh heavily on reliability and availability.

In reality, comparing the MSH to a used diesel compressor means choosing between a controlled investment and a mechanical gamble with unpredictable maintenance costs.

At first glance, purchasing a used diesel compressor — typically 5 to 8 years old, or even older — may seem attractive due to its lower price. However, this apparent saving must be reconsidered when evaluating the real long-term operating costs.

Less Maintenance, More Availability

The MSH MacFarmer, developed by MAC3, is specifically designed for agricultural use. It mounts directly onto the tractor’s rear or front linkage (or can be handled with forks) and operates via the hydraulic circuit: no dedicated combustion engine, no fuel to manage, no unreliable starting issues.

The direct result: combustion-related breakdowns and associated maintenance costs are eliminated. In operation, the MSH requires up to 77% lower maintenance costs than an equivalent diesel compressor, with fewer parts, fewer lubricants, fewer service interventions, and less downtime. A simple annual maintenance kit is all that’s needed.

77% lower maintenance costs, 100% ease of use.

Professional Performance, Built for the Field

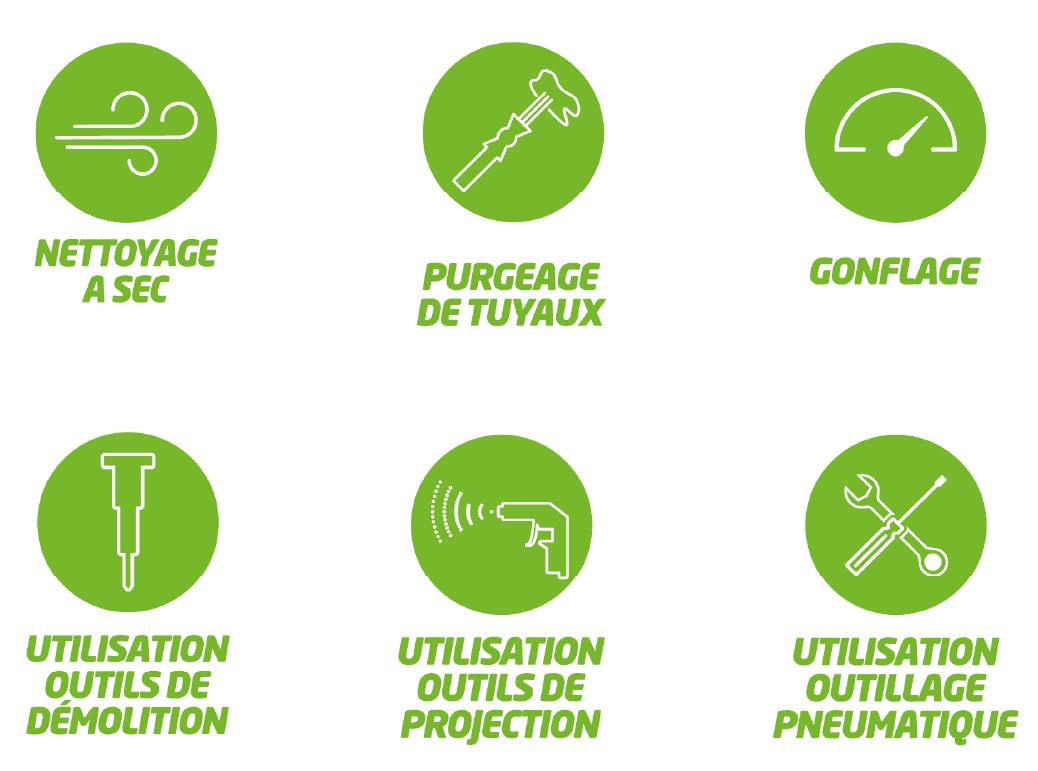

When it comes to performance, the MSH makes no compromises: up to 2,500 L/min at 7 bar — more than enough to handle most common agricultural tasks such as blowing, dry cleaning, pipe purging, and light construction work. Designed with and for farmers, it integrates naturally into daily farm operations: it follows the tractor, connects instantly to the hydraulic circuit, and becomes operational within seconds.

Ergonomics Designed for Farmers

Compared to a worn-out used construction compressor — often noisy with age and rarely optimized for agricultural needs — the MSH MacFarmer is compact, easy to mount, and purpose-built for farm use. It can be equipped with practical options (20 m hose reel, storage boxes, net wrap holder and wrapping net support) and is manufactured in France, CE certified, ensuring safety and compliance.

In short: a used compressor adapts. The MSH integrates.

A Smart Long-Term Choice

Although the purchase price of the MSH MacFarmer may appear higher than that of an aging compressor with an uncertain history, it represents a clear, controlled, and sustainable investment: no unpleasant surprises, no hidden costs.

Above all, the key issue is avoiding downtime when blowing and cleaning equipment is critical — during harvest, silage, haymaking, or tight weather windows. With the MSH, the compressor is available at the right time: it follows the tractor and becomes operational within seconds.

Conversely, investing in an older-generation compressor (5–8 years or more) means blindly trusting an uncertain maintenance history: a breakdown or unreliable starting can disrupt farm organization.

More reliable. Lower maintenance costs. Easier to use.

The MSH MacFarmer naturally stands out as the thoughtful and sustainable choice, perfectly suited to the realities of modern farming — the right tool, at the right time.