Add value to your installations with MAC3 AuditAir

The compressed air energy audit is an essential step for any industrial company wishing to improve its energy efficiency. By identifying areas of waste and accurately measuring equipment performance, it becomes possible to reduce energy consumption, cut operating costs and increase overall plant profitability.

With MAC3 AuditAir, MAC3 provides manufacturers and service providers with a comprehensive, accurate and innovative tool for 360° analysis of compressed air networks. The solution has been designed to provide a clear, detailed view of every component in the system, to identify losses, optimize settings and ensure more sustainable, cost-effective operation.

Comprehensive technology for your energy audits

Measure, analyze and optimize your installations

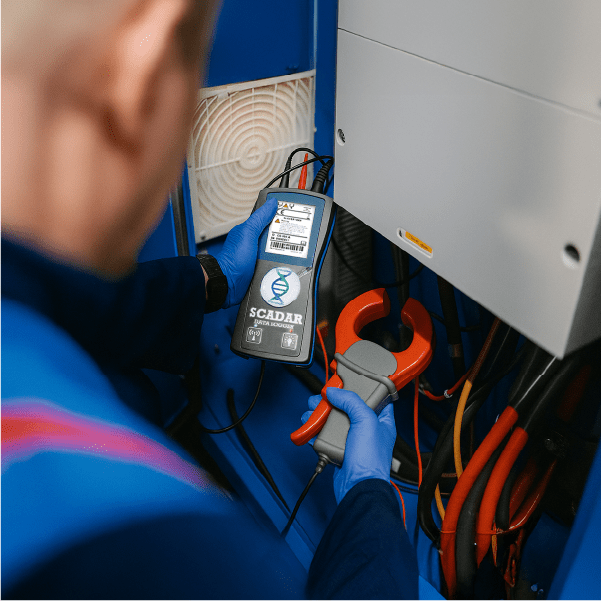

MAC3 AuditAir technology has been developed to meet all energy audit requirements, whatever the type of compressed air system and the size of the installation. It is equally suited to small stand-alone units and complex industrial networks. Thanks to its flexible architecture and high-precision sensors, it can measure all essential compressed air network parameters.

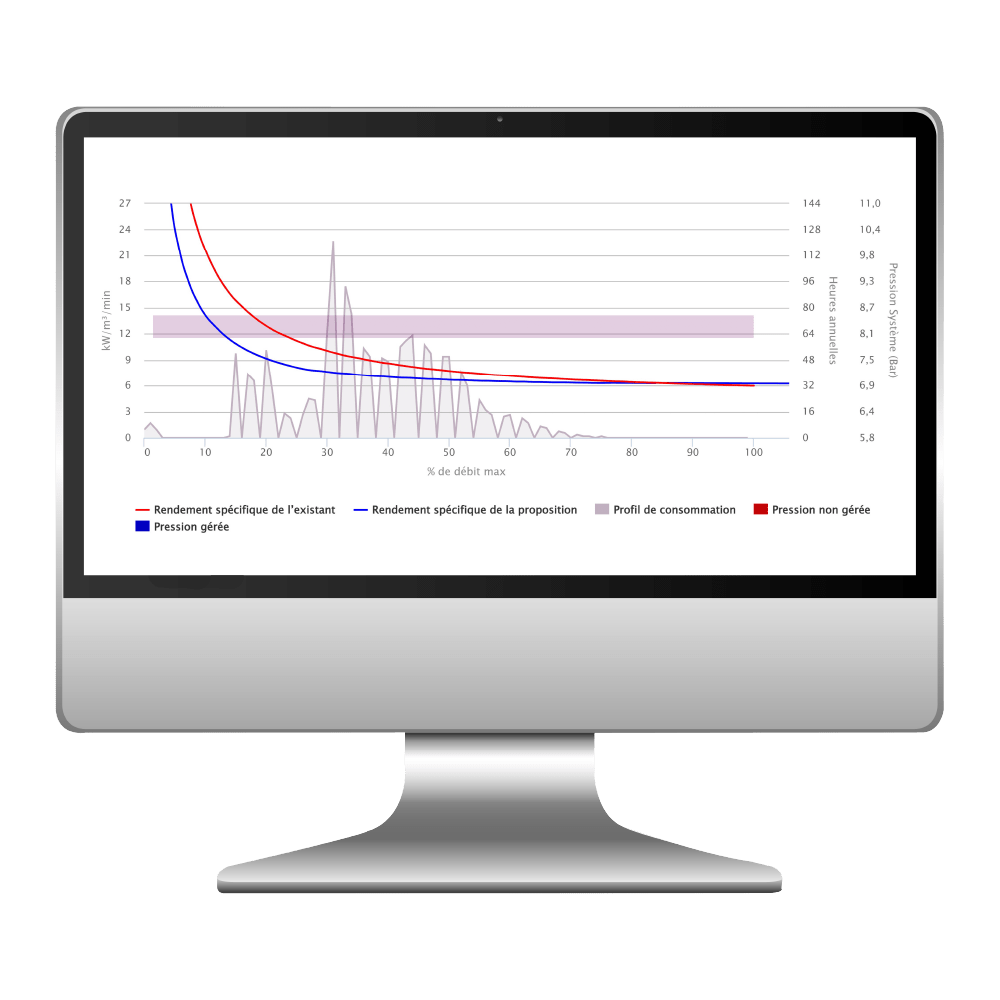

Each MAC3 AuditAir audit provides a clear and precise view of the compressed air system’s energy behavior.

In its standard configuration, the solution measures pressure, current and voltage, providing a complete analysis of the network’s electrical and pneumatic performance.

Depending on the specific needs of the installation, other sensors – such as temperature, dew point or flow – can be added to further enhance the energy diagnosis.

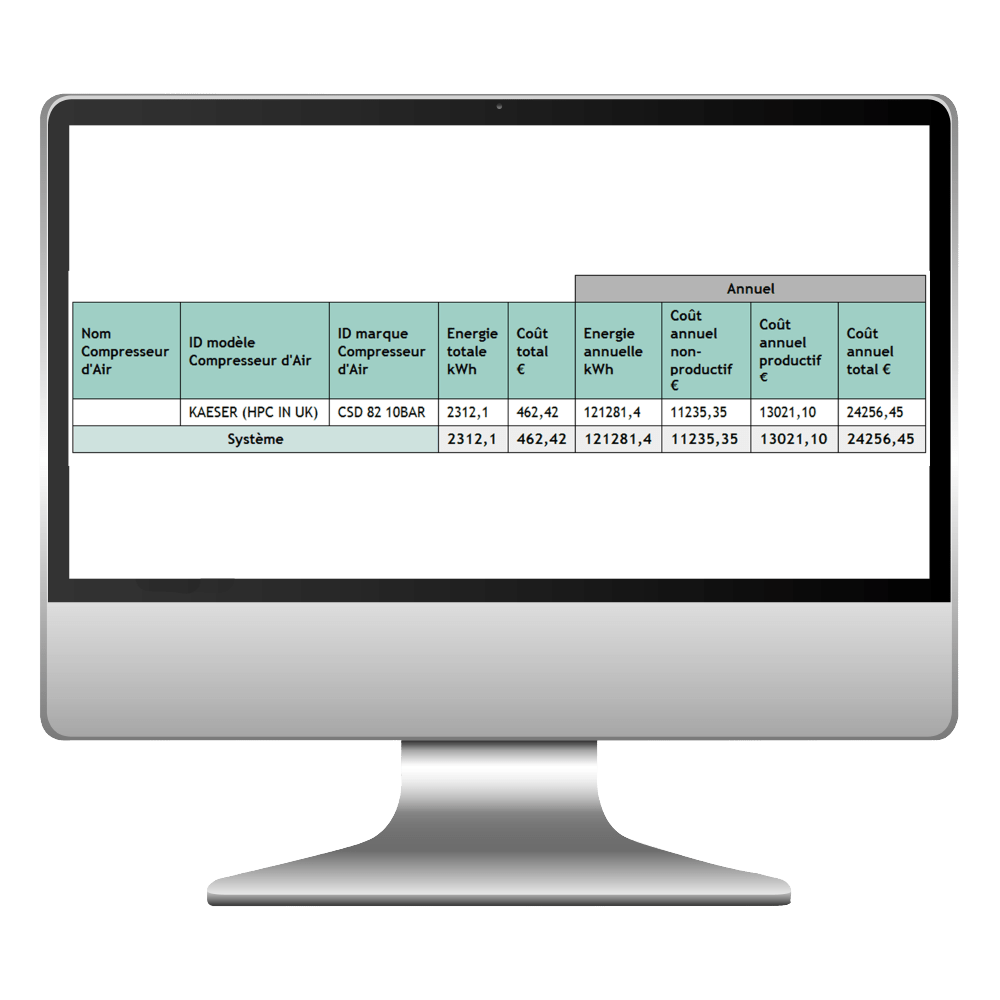

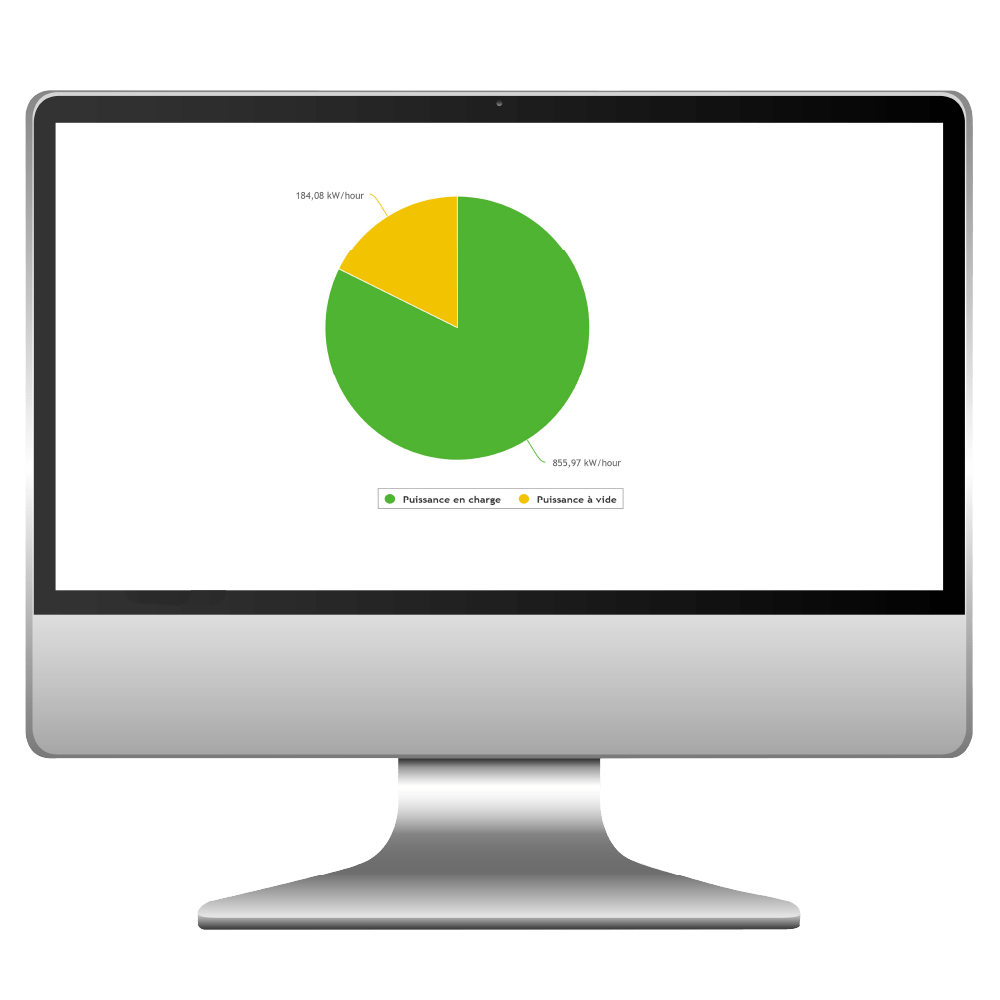

These data enable us to distinguish between power that is truly productive and that which does not contribute to performance, and thusidentify priority areas forimprovement. Based on these analyses, companies can reduce energy losses, improve equipment reliability and extend equipment life.

The information collected is then transmitted in real time via a connected base station, guaranteeing smooth, secure data transfer to the MAC3 AuditAir online portal. This connectivity ensures continuous monitoring and centralized management of all ongoing audits.

MAC3 AuditAir Pack

The MAC3 AuditAir package brings together all the equipment needed to carry out complete, stand-alone energy audits.

-

Connected base station (up to 25 simultaneous audits)

-

Current/voltage recorders (50A and 800A)

-

Pressure recorders (16 bar and 60 bar)

-

Temperature recorders (up to 200°C)

-

Flow recorder (185 m/s)

-

Dew point recorder (-80°C)

-

4-20 mA recorder for additional sensors

Thanks to this comprehensive instrumentation, the MAC3 AuditAir system captures every critical data item in the network, providing a detailed analysis of the energy behavior of the entire plant.

An intelligent platform for data processing and analysis

The data collected during audits is then processed via the MAC3.SCADAR.NET online platform, a cloud-based tool designed specifically for the management and operation of energy audits. This digital environment enables new audits to be configured, data to be analyzed and professional reports to be generated automatically.

Up to ten new audits can be managed each month from this interface. The system incorporates advanced modules for creating automatic tables and curves from recorded data, making it easy to visualize and understand network performance. It also features energy simulation, detailed report generation and compressor database management functions.

Thanks to this platform, every user benefits from a comprehensive management tool that simplifies decision-making and highlights concrete energy-saving levers. The entire process, from data collection to analysis, is centralized and optimized for maximum time savings and reliability.

Why choose MAC3 for your energy audits?

With MAC3 AuditAir, you get a turnkey solution, from data measurement to in-depth analysis. This tool is a real competitive lever, enabling you to enhance your customers’ energy performance while reinforcing the added value of your own services.

By integrating anenergy audit into your industrial approach, you can contribute to more sustainable resource management, while optimizing your production costs and profitability.