Integrated aftercooler available on MAC3 2000 to 3000-litre compressors

Our design department has therefore looked at the MSP2000 (flow rate 2000 l/min), MSP2500 (flow rate 2500 l/min) and MSP3000 (flow rate 3000 l/min) compressors to develop a new option: the integrated compressed air aftercooler. This option is already available on the MSP5000 (5000 l/min flow rate compressor).

THE ADVANTAGES OF THE COMPRESSED AIR AFTERCOOLER

When a compressor produces compressed air, it is fed by atmospheric air. This air is always composed of water vapor and when the air is compressed, the concentration of water increases.

In order to avoid the production of air loaded with water molecules, a treatment of the air is necessary in order to cool it down, allowing the transformation of the steam into liquid (role of the exchanger), then to capture this water (role of the centrifugal water separator) and to extract it from the air circuit.

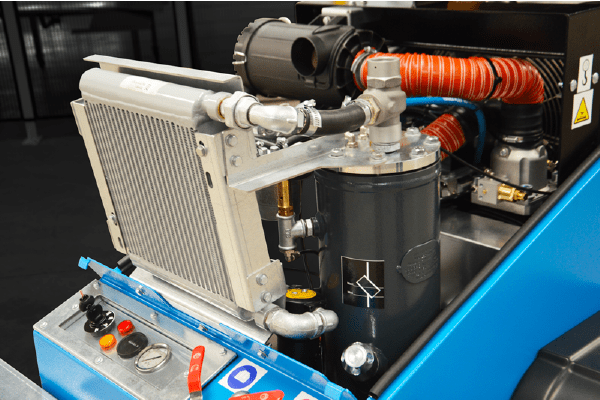

AN OPTION INTEGRATED IN THE HEART OF THE COMPRESSOR

The MAC3 design office has worked to integrate this option without changing the proportions of the compressors. The addition of the aftercooler does not affect the access to the vital parts of the compressor, thus maintaining its ease of maintenance.

This option provides real value to users of the MSP Series compressors, enhancing the versatility and suitability of these machines for the field.