MAXIMUM FLEXIBILITY

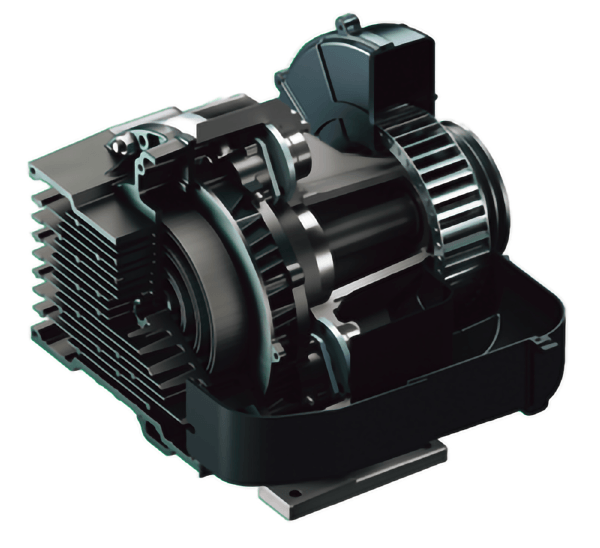

From 1.5 to 30kW, the MSS range can meet a wide range of oil-free air requirements.

The MSS range offers models with up to 4 compressors in the same chassis and is divided as follows

- S = 1 scroll compression unit

- D = 2 spiral compression units

- T = 3 spiral compression units

- Q = 4 scroll compression units

The multi-compressor models D, T and Q, are driven by an advanced electronic controller, allowing to manage the start/stop, rotation and balancing of the compression units, with the main objective of a perfect match between consumption and production of compressed air.

Finally, the S models with only one compression unit can be delivered mounted on an air receiver with refrigeration dryer and filtration.