STUDY OF CUSTOMIZED SOLUTIONS

MAC3, the French expert in compressed air solutions, is now leveraging its expertise to provide fully customized, turnkey installations for your industrial applications. We support you from defining your needs to commissioning and training your teams, managing every step entirely in-house.

Conception & Ingénierie la puissance d’un bureau d’études intégré

At the heart of every custom project lies thorough engineering work.

At MAC3, our engineering department, equipped with advanced software and a full range of measurement instruments, fully demonstrates its ability to turn your requirements into reliable technical solutions.

We analyze your specifications, carry out technical studies, 3D design, and see the process through to prototype validation.

This integrated approach ensures complete control over interfaces, optimized performance, and fast execution.

3D Mechanical Design (TOPSOLID and SOLIDWORKS)

STEP file for client approval

Piping and Instrumentation Diagram (P&ID)

Electrical diagrams

User manuals and preventive maintenance guides

Test reports

Manufacturing & Assembly

Complete Industrial Expertise

Once the design is approved, MAC3 teams take full responsibility for production in our workshops, with experienced assemblers, pipefitters, electricians, and commissioning specialists.

Located in Auvergne-Rhône-Alpes near Saint-Étienne, on a 5,500 m² site, our facilities include sheet metal work, machining, assembly, testing, and shipping.

You benefit from a single point of contact who oversees every step: chassis fabrication or container preparation, stainless steel piping assembly, electrical wiring, integration of control panels, dry-run testing, and turnkey delivery.

Your Turnkey Project – From Concept to Operation

Every custom MAC3 project follows a structured methodology, ensuring transparency, efficiency, and full compliance.

Preparation / Validation of Specifications

Consideration of client constraints

Technical Studies

3D design of the installation

Electrical, pneumatic, and instrumentation studies

Custom Manufacturing

Tailor-made chassis fabrication for skid-mounted installations

Customization and preparation of maritime containers

Assembly in Our Workshops

Installation of compressed air networks in stainless steel piping

Electrical distribution board and equipment wiring

Testing and Start-Up in Our Workshops

Customer acceptance – FAT (Factory Acceptance Test)

Configuration of remote connection interfaces

User Training

Delivery of a complete technical documentation package

If you’d like, I can also format everything as a polished brochure-ready version.

EXAMPLES OF REALIZATIONS

CUSTOMIZED SOLUTIONS FOR THE INDUSTRY

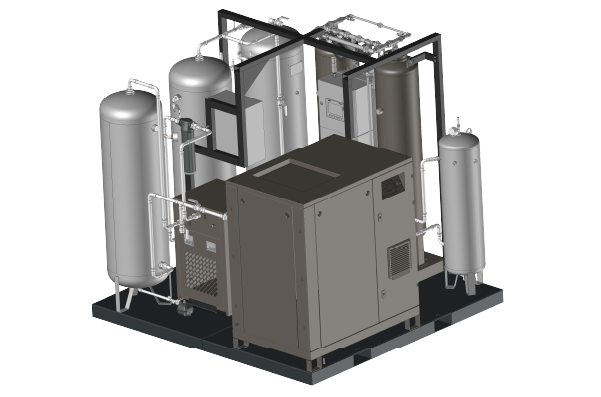

Installation in a container

- Stainless steel distribution network

- Stainless steel condensate collection

- Electrical control cabinet with container wiring

- Remote control & monitoring

Soundproofing and insulation of the container

Ducting and ventilation

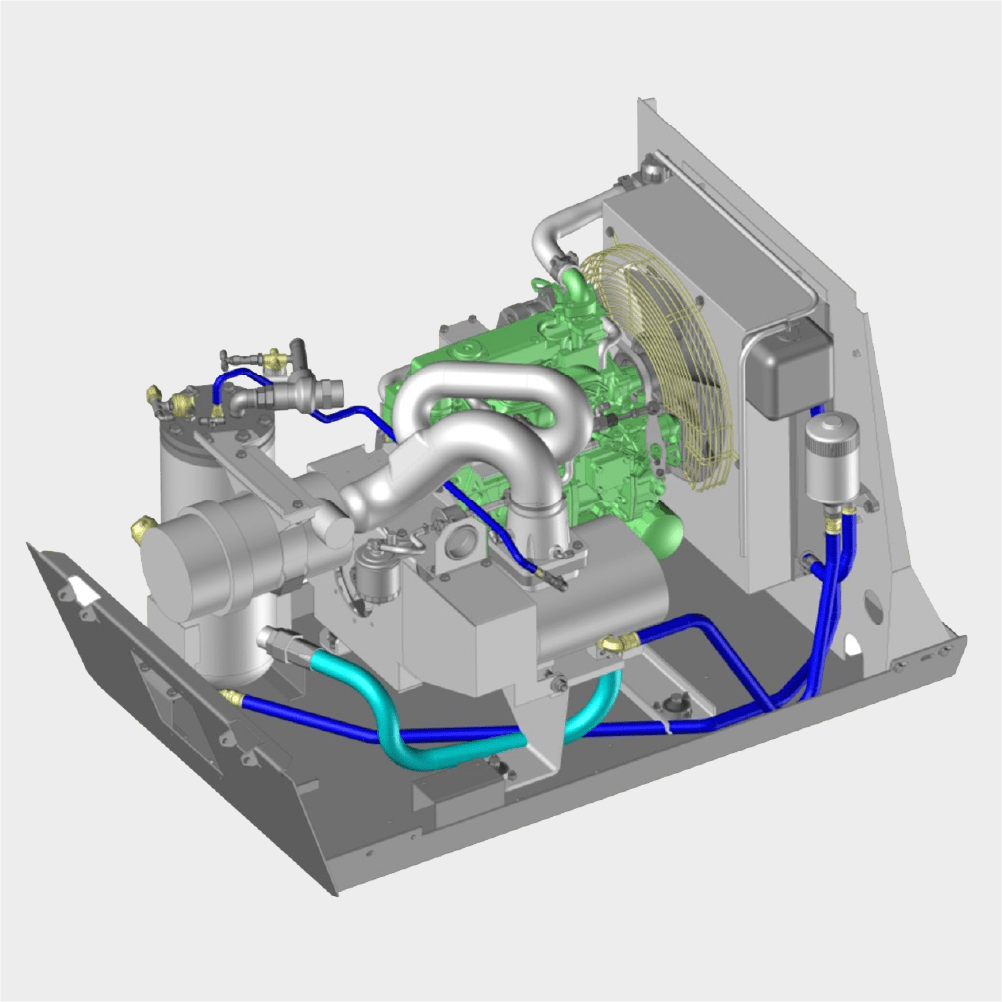

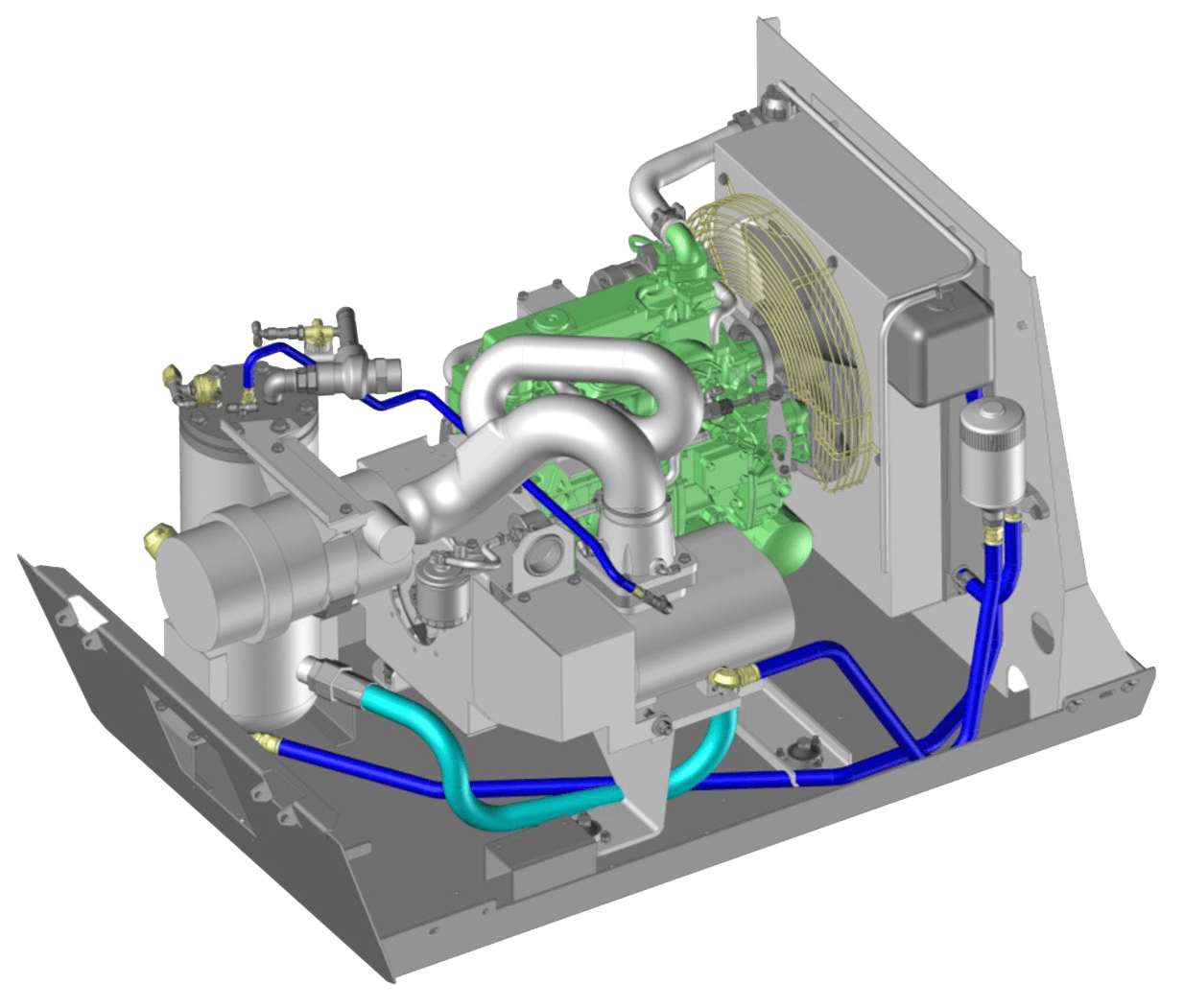

Installation on SKID

- Stainless steel distribution network

- Stainless steel condensate collection

- Electric control cabinet with SKID wiring

- Remote control & monitoring

Easy handling

APPLICATIONS

- Mobile facilities

- Compressed air production expansion

- Building extension

- Generation of industrial gases

CUSTOMIZED CONSTRUCTION SOLUTIONS

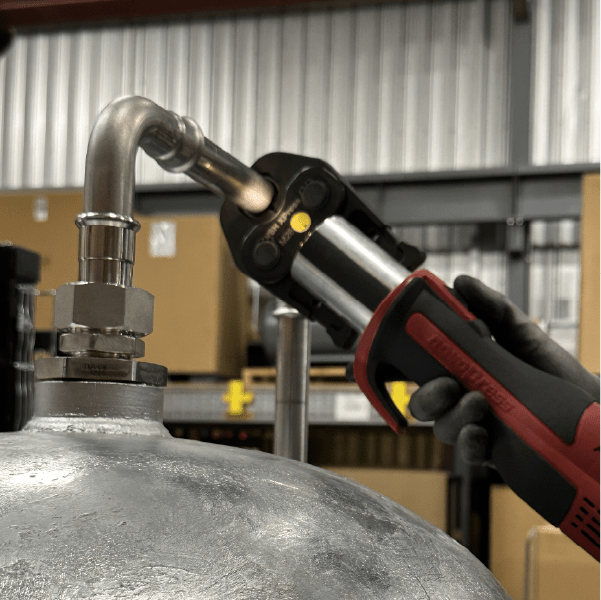

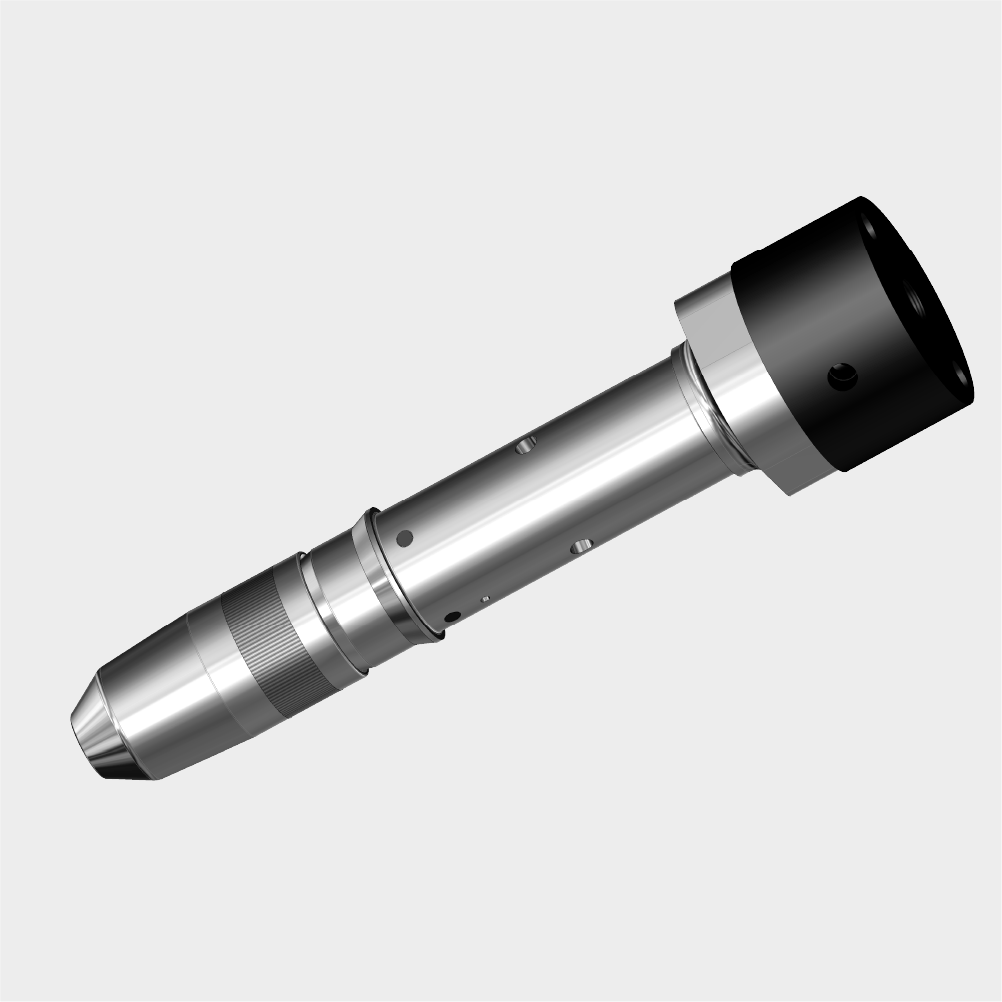

- High temperature resistant pick hammer

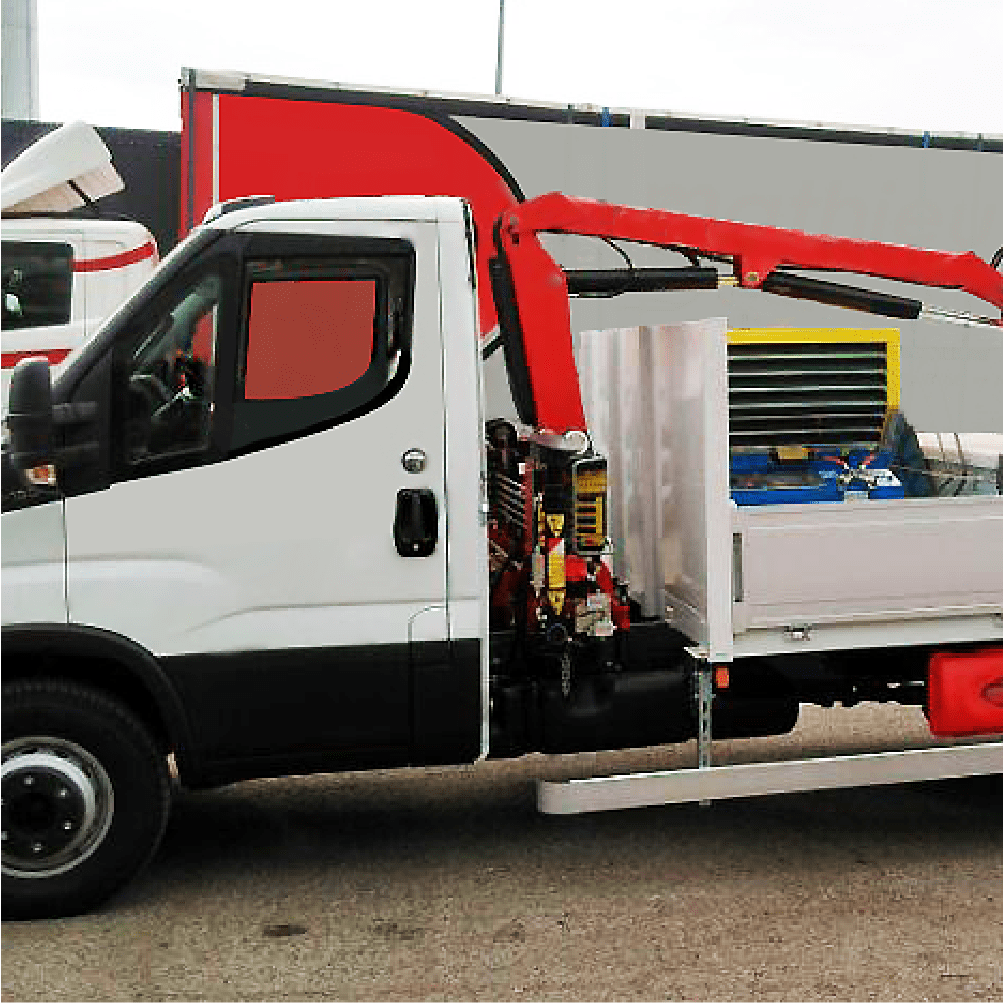

- Integrated compressor on truck

- Motorcycle compressor unit on chassis

- Remote dashboard

- …

Because your activity may require the use of products with certain requirements, MAC3 develops for you products that will meet your specifications.

For the realization of specific requests, we go through a set of rigorous steps that will allow us to realize your project.

- Presentation of the specifications

- Feasibility study

- 3D Design

- Prototypage

- Pre-series validation

- Finalization of the project